Service of a pocket watch

Mechanical watches is fascinating. A mechanical timepiece that gets its energy from unwinding a tightly coiled flat spring. All this energy does feed another spring-driven balance wheel that oscillates back and forth in a given frequency. All without any batteries. Isn't that cool?

Mechanical watches is quite expensive and need regular services, so I bought a no-name brand pocket watch that suddenly could stop tick and didn't keep time very well. A perfect restoration project for me.

Here is the watch I bought:

The watch

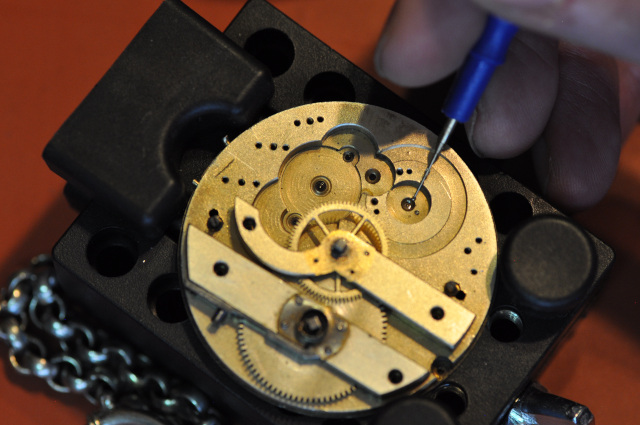

The lovely clockwork from the backside:

The dial is in a quite bad shape. I have not decided if I should try to get/make a new one or just let it be.

Here are the main components of the watch.

| A: | Mainspring |

|---|---|

| B: | Jewels |

| C: | Gear train |

| D: | Balance wheel with escapement mechanism |

Clockwork

A clockwork consists of mowing parts, mostly gears, and all friction does not work for the good. One way to reduce friction is to use jewel bearings as those are much harder than metal. Nowadays these jewels are made out of synthetic rubies or sapphires.

Oil does also help to reduce friction.

The movement parts of a mechanical watch have at least these five parts:

Mainspring

The mainspring is a torsion spring made out of spring steel and is the power source of the whole watch. When you wind up a clock, it is this spring that you are tensioning.

Wristwatches could have an automatic wind up that use your arm movement to tension the spring.

Gear train

The gear train transmit the force of the mainspring to the balance wheel and also, by gear ratios, divide the rotation into convenient time of hours, minutes and seconds.

Usually a clockwork consists of five wheels, these are:

| First wheel: | Attached to the mainspring and slowly unwinds and feed the other wheels. |

|---|---|

| Second wheel: | This wheel turns once per hour and also drives the minute wheels and third wheel. |

| Third wheel: | Used to shift down the speed of the forthcoming gears. |

| Forth wheel: | Turns once per minute, so it holds the second hand. |

| Escape wheel: | Releases one tooth at a time and keeps the balance swinging by giving a small push on the fork each time. |

Balance wheel

This part is the coolest.

It is an oscillating part that work as the timekeeping device in the clockwork. In mechanical clocks, the heart is a torsion spring (known ans hairspring) that form a harmonic oscillator which oscillates at a certain rate due to its resonance. The length of the hairspring determine its resonant frequency, so many clocks does have a lever that simply adjust the length of the spring, this lets you tune the clockwork.

After 1970, these mechanical timekeeping parts was replaced by quartz crystals with better timekeeping. But not as cool as springs.

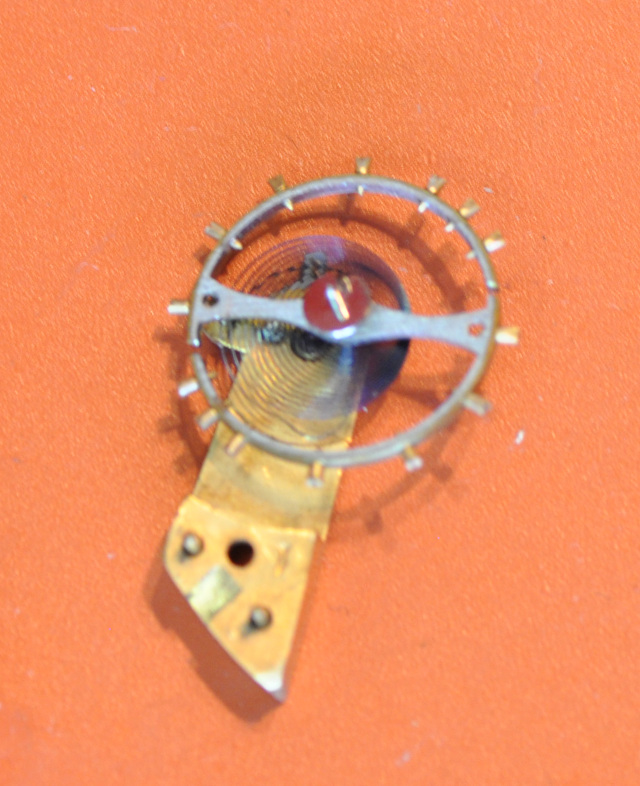

See the lever for adjusting hairspring length on top of the balance wheel:

Escapement

The escapement makes the balance rotate by giving small pushes with enough energy to feed the oscillator.

The goal

The goal is to disassembly all parts, clean it up and apply oil for all mowing parts.

Disassembly

First remove the hands. I put a paper beneath then hands and dial to not scratch the dial even more.

These two gears is the reduction gears for the hour hand and minute hands. Those were locked in place by the dial only, so we could just take them out:

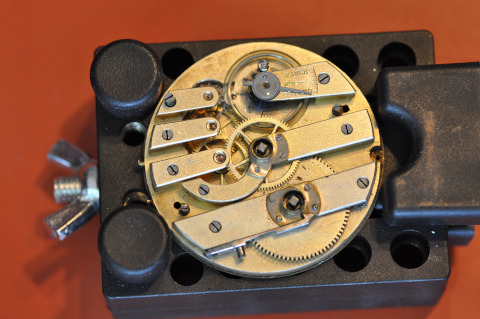

Put the clock in a fixture for easier disassembly:

First I remove the balance wheel. We have to be careful with the hair spring. If we get a crease on it it will not oscillate at the right frequency. Here it is:

Then I remove the fork and escape wheel. Here is the fork:

All parts disassembled. I have not open up the mainspring as I do not have tools to put it back. Now it is time to clean the parts. I bought small baskets to be used in an ultrasonic cleaner, but somehow I lost the baskets. So I clean every part by hand with isopropanol to dissolve all old residues from oil.

| A: | Balance wheel |

|---|---|

| B: | Fork |

| C: | Minute and hour gear |

| D: | Mainspring gear |

| E: | Hands |

| F: | Dial |

| G: | Escape wheel |

| H: | Train gears |

Clean up and oil

I use isopropanol and a cotton top to rub the parts clean.

After that it is time to oil the mowing parts. Actually you should have oil of different viscosity for the different parts, but I use Moebius 8000 for everything, which is a general purpose oil.. which is probably not good at anything, but better than nothing. The reason is that I do not want to spend too much money on this clock and oil costs about 50 bucks per bottle

Apply oil on all jewels.

Assembly

The assembly was not as hard as i imagined that it should be. It turned out smooth, just doing things in the reverse order.

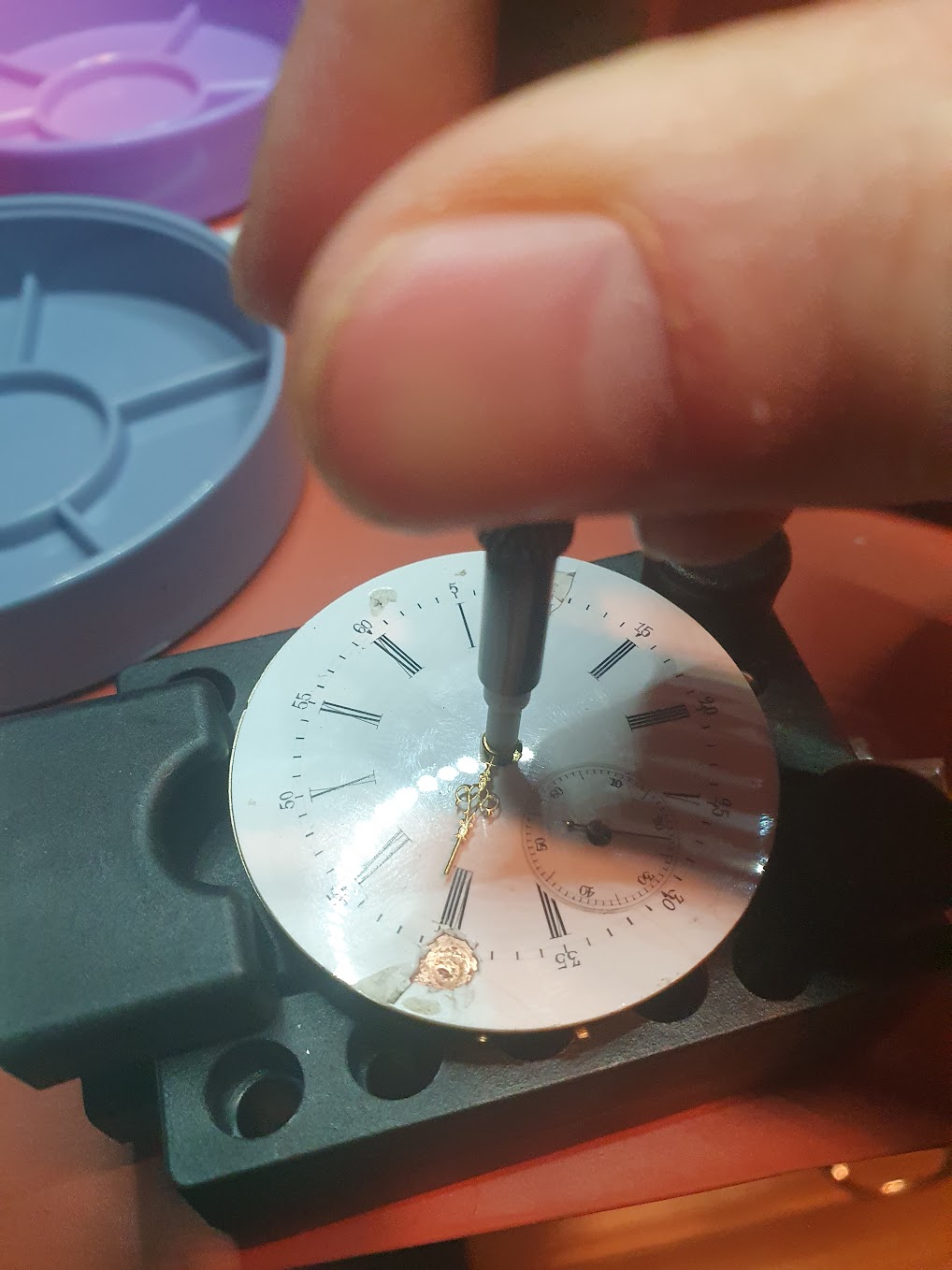

The last step before putting the clockwork back into the case is to press on the hands:

The result

I have let the clockwork run for 24h now, it has not stopped a single time and, what I can tell, it has drifted a couple of seconds at most. I can probably get it better by adjusting the length of the hair spring with the lever, but it takes a few more days to evaluate.